Best Aggregate Manufacturer Chennai | Aggregate Suppliers in Chennai

Fine aggregate is on of the major constituents of concrete which can influence concrete mix design substantially. Various factors such as fine aggregate fineness modulus, moisture content, specific gravity, and silt content affect the mix proportions of concrete. Aggregate Suppliers in Chennai

Aggregate Suppliers in Chennai

Fine aggregate moisture content influences the mix proportion substantially. It specifies the amount of water that may be added to subtracted to the mixture. Mix design of concrete cannot be carried out without specific gravity of fine aggregate, and higher specific gravity produced stronger concrete. Finally, the presence of silt in sand would increase water demand in concrete mixture and may reduce concrete strength. Aggregate Suppliers in Chennai

1. Fineness Modulus

It is one of the factors that influence concrete mix design since it controls the proportion of sand in concrete mixture. The fineness modulus of sand varies from 2 to 4.

Blue Metal in Construction

Premier Construction Aggregate: At Vignesh Aravind Transports, we recognize blue metal’s critical role in providing durability and stability, essential for enhancing the structural integrity of a wide range of projects.

Diverse Applications: Our blue metal is perfect for various construction needs, including concrete mixes, and driveway paving, and as a foundational layer for roads, underscoring its versatility and indispensability.

Quality-Sourced Material: As one of the top blue metal dealers in Chennai, Vignesh Aravind Transport ensures our blue metal is sourced from the finest quarries, offering consistency and premium quality for superior construction outcomes.

Enhanced Strength and Durability: Our focus is on supplying the blue metal that contributes significantly to the longevity and robustness of construction projects, establishing us as a preferred choice among builders and contractors.

Your Trusted Supplier in Chennai: Vignesh Aravind Transport, a renowned name among blue metal suppliers in Chennai, is committed to delivering only the best quality blue metal, ensuring your projects benefit from materials that meet the highest standards.

Choose Quality with Vignesh Aravind Transport: Opting for blue metal from Vignesh Aravind Transport guarantees your construction projects are built on a foundation of unparalleled quality, promising durability and structural integrity.

Blue Metal: Backbone of Infrastructure Development and Road Construction

Building Roads to Last: Blue metal is a crucial element in road construction, laying the groundwork for long-lasting roads and thoroughfares.

Blue metal aggregates are critical in building strong road bases that provide stability and lifespan in infrastructure projects.

Blue metal’s porous nature allows for good water drainage, eliminating waterlogging and lowering the danger of road damage from erosion and flooding.

Precision Engineering: Interestingly, the size and grading of our blue metal aggregates are carefully managed to fit exact standards, ensuring excellent compaction and structural integrity in road building.

Versatile Applications: In addition to roads, our blue metal is used to build bridges, culverts, and other critical infrastructure, demonstrating its adaptability and importance in civil engineering projects.

Strategic Sourcing: At Vignesh Aravind Transports, one of the leading blue metal suppliers in Chennai, we methodically find and distribute high-quality blue metal while adhering to severe standards to suit the demanding requirements of infrastructure and road building.

Economic Impact: The efficient use of our blue metal in infrastructure development boosts economic growth by enhancing connections, enabling commerce, and promoting regional development.

We, at Vignesh Aravind Transports, the well-known blue metal dealers in Chennai, guarantee that each of our deliveries fulfils strict criteria, allowing for flawless building operations and long-lasting road networks.

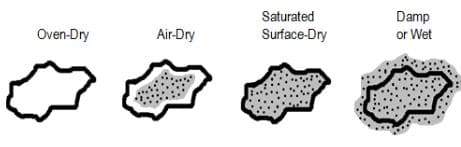

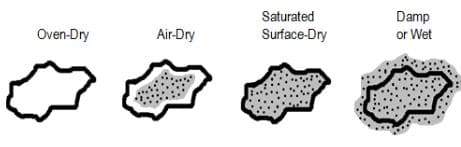

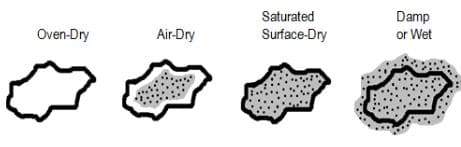

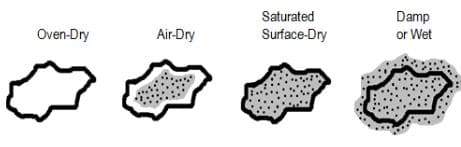

2. Moisture Content

It is undeniable that all aggregates contain some moisture based on moisture condition of the storage area and particle porosity. Red Soil suppliers in chennai

Frequently, fine aggregate is in wet condition with surface moisture up to five percent.

3. Specific Gravity

Higher the specific gravity heavier is the sand particles and higher is the density of concrete. In contrary, a lower specific gravity of sand will result in lower density of concrete. The specific gravity of fine aggregates found in Pune region varies from 2.6 to 2.8. M sand suppliers chennai

4. Silt Content

This is found by wet-sieving of sand and material passing 75-micron sieve is classified as silt. This silt affects the workability of concrete, results in higher water/cement ratio and lower strength. The upper limit for 75-micron sieve in case of sand is 3% by weight.

Frequently, fine aggregate is in wet condition with surface moisture up to five percent.

3. Specific Gravity

Higher the specific gravity heavier is the sand particles and higher is the density of concrete. In contrary, a lower specific gravity of sand will result in lower density of concrete. The specific gravity of fine aggregates found in Pune region varies from 2.6 to 2.8. M sand suppliers chennai

4. Silt Content

This is found by wet-sieving of sand and material passing 75-micron sieve is classified as silt. This silt affects the workability of concrete, results in higher water/cement ratio and lower strength. The upper limit for 75-micron sieve in case of sand is 3% by weight.

Frequently, fine aggregate is in wet condition with surface moisture up to five percent.

3. Specific Gravity

Higher the specific gravity heavier is the sand particles and higher is the density of concrete. In contrary, a lower specific gravity of sand will result in lower density of concrete. The specific gravity of fine aggregates found in Pune region varies from 2.6 to 2.8. M sand suppliers chennai

4. Silt Content

This is found by wet-sieving of sand and material passing 75-micron sieve is classified as silt. This silt affects the workability of concrete, results in higher water/cement ratio and lower strength. The upper limit for 75-micron sieve in case of sand is 3% by weight.

Frequently, fine aggregate is in wet condition with surface moisture up to five percent.

3. Specific Gravity

Higher the specific gravity heavier is the sand particles and higher is the density of concrete. In contrary, a lower specific gravity of sand will result in lower density of concrete. The specific gravity of fine aggregates found in Pune region varies from 2.6 to 2.8. M sand suppliers chennai

4. Silt Content

This is found by wet-sieving of sand and material passing 75-micron sieve is classified as silt. This silt affects the workability of concrete, results in higher water/cement ratio and lower strength. The upper limit for 75-micron sieve in case of sand is 3% by weight.

Article Source : The Constructor